Diesel Locomotive Gearbox Repair

Offloading the damaged locomotive truck at FMW’s machine shop - the donor trucks can be seen at left.

FMW was retained by GE Power, of Schenectady, New York, to assist it in returning a 110-ton center cab switching locomotive to operational condition. The locomotive had been damaged during shipment to GE, resulting in damage to the traction motor support bearings, journal surfaces, and gearbox.

To repair the locomotive, FMW used parts off of a donor set of trucks to replace the gearbox and traction motor. Specifically, FMW:

Lifted the locomotive using GE’s overhead cranes and remove the subject truck;

Shipped the subject truck to the FMW facility in Watervliet, New York;

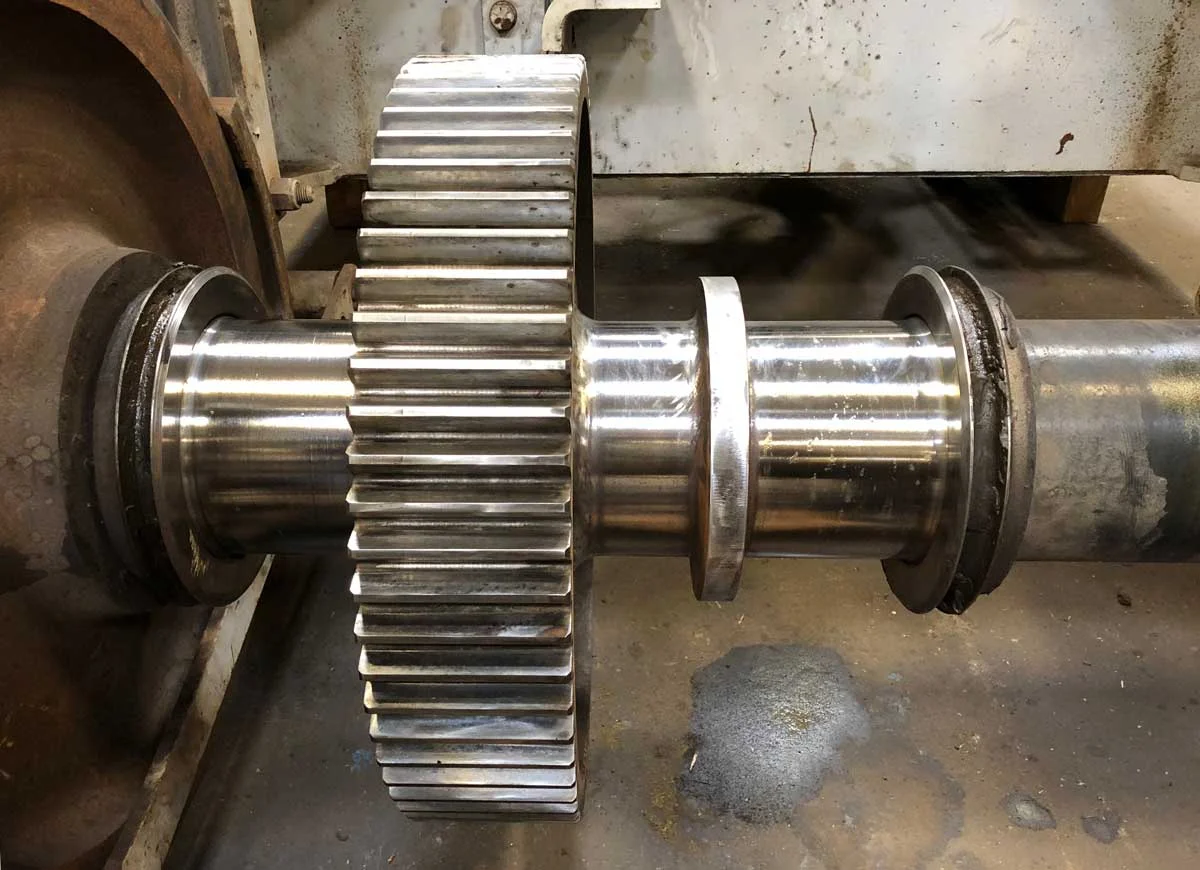

Cleaned up the journals and spur gear;

Inspected the traction motor with a Megger to verify integrity;

Disassembled and inspect a “donor” truck for key bushings;

Reassembled and test the truck; and

Returned the truck to GE, and commissioned the locomotive.

The locomotive was taken out of service on a Thursday and put back into service by the following Monday, including both lifts, to minimize downtime at the facility.