Locomotive Bearing Box, Crankpin, and Wheel Work on U.S. Sugar No. 148

FMW was retained to oversee a variety of detailed engineering and fabrication tasks associated with the driving wheels and driving boxes of U.S. Sugar (USS) steam locomotive No. 148 (No. 148). Originally built for the Florida East Coast Railway in 1920, the light 4-6-2 type locomotive is in the midst of an extensive overhaul to operation for use by USS on its Florida sugar plantation railroad. In particular, FMW was tasked with: 1) wheelset work; 2) crankpin work; and 3) driving box work.

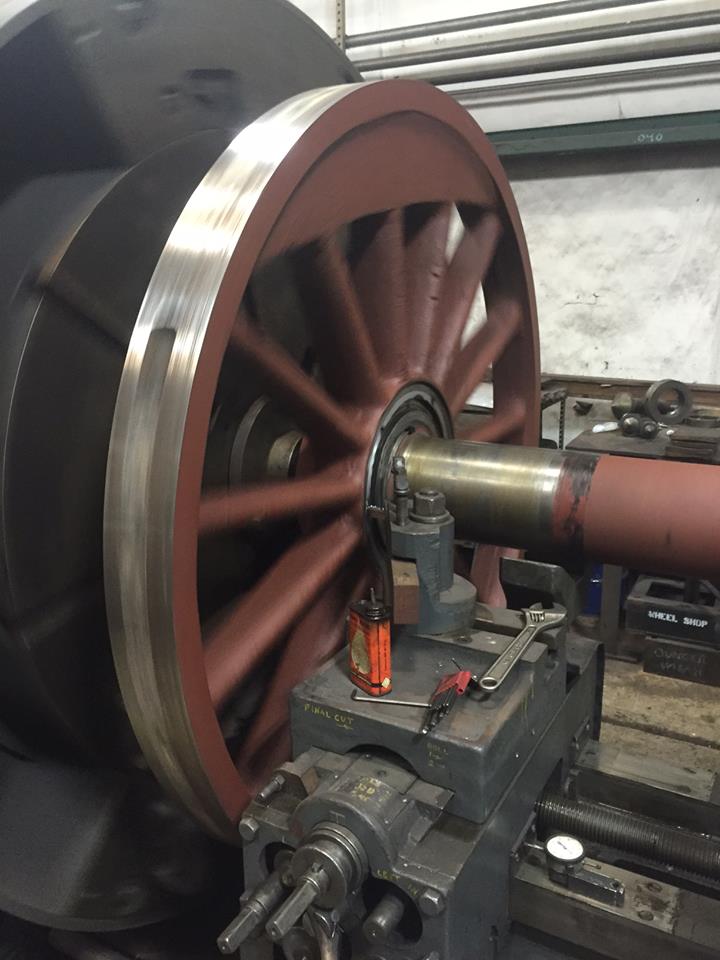

Wheelset Work | FMW’s Shane Meador began its wheelset work with a detailed inspection of each wheel center, including removing the original tires, sandblasting, and dye penetrant testing the wheel centers. This revealed the wheel centers to have cracks from years of use. Employing railroad standard practice from the era, FMW ground out the cracks and weld-repaired the wheel centers. Then, FMW employed a specialty wheel and journal lathe to re-profile the wheel centers, re-profile the journals, and roll burnish the journals to harden the surfaces. Once this work was completed, Meador ordered and installed new tires for all three wheelsets.

Crankpin Work | FMW burned out the crank pins from each of the wheel centers and undertook quartering of the crank pin bores. This work, as per industry practice, was done after the new tires had been applied to the wheel centers to ensure that the quartering of the bores and pins would not be impacted by the flex associated with the application of new tires. Then, using the original pins as a guide, FMW’s Fengler created new 3D CAD drawings of each of the crank pins. These drawings were used to rough CNC-machine new pins which, after their delivery, were finish machined by Meador to-fit. Finally, once all of the quartering boring and crankpins were completed, Meador used liquid nitrogen to shrink the pins so that they could be inserted into the bores, by hand.

Driving Box Work | FMW was initially tasked with undertaking an inspection of the existing driving boxes on No. 148. The original boxes were found to be quite worn, thus it was determined that manufacturing new driving boxes would be a better cost benefit than repairing the worn out components that came with the locomotive, and it instructed FMW to undertake that work. FMW reverse-engineered the existing boxes, creating 3D CAD drawings, one each for the main and other than main boxes. As part of this process, FMW took into consideration the request to convert the locomotive from “grease cake” lubrication to a force feed lubrication, as was commonplace with the Southern Pacific Railroad. This force feed oil system was also undertaken by Meador on Southern Railway Nos. 630 and 4501, and it has proven reliable over tens of thousands of miles of operation. This system is also used by SP 4449 which, too, has proven quite reliable on the road.

Once each box design was approved, FMW acquired the raw material (a 12 inch thick slab of steel) and began fabrication. Employing a combination of CNC machining and manual machining, FMW: 1) rough machined the boxes; 2) detail machined the boxes; 3) machined and press-fit new crown brasses and hub liners; 4) applied Babbitt to the journal bearing surface; 5) machined the babbitt to-fit; 6) machined all required lubrication paths on the boxes; and 7) finish machined the wedge/shoe surfaces and spreader plates.