Steam Locomotive Restoration Making Tracks

The restoration of a mechanical engineering landmark emerges in Tennessee.

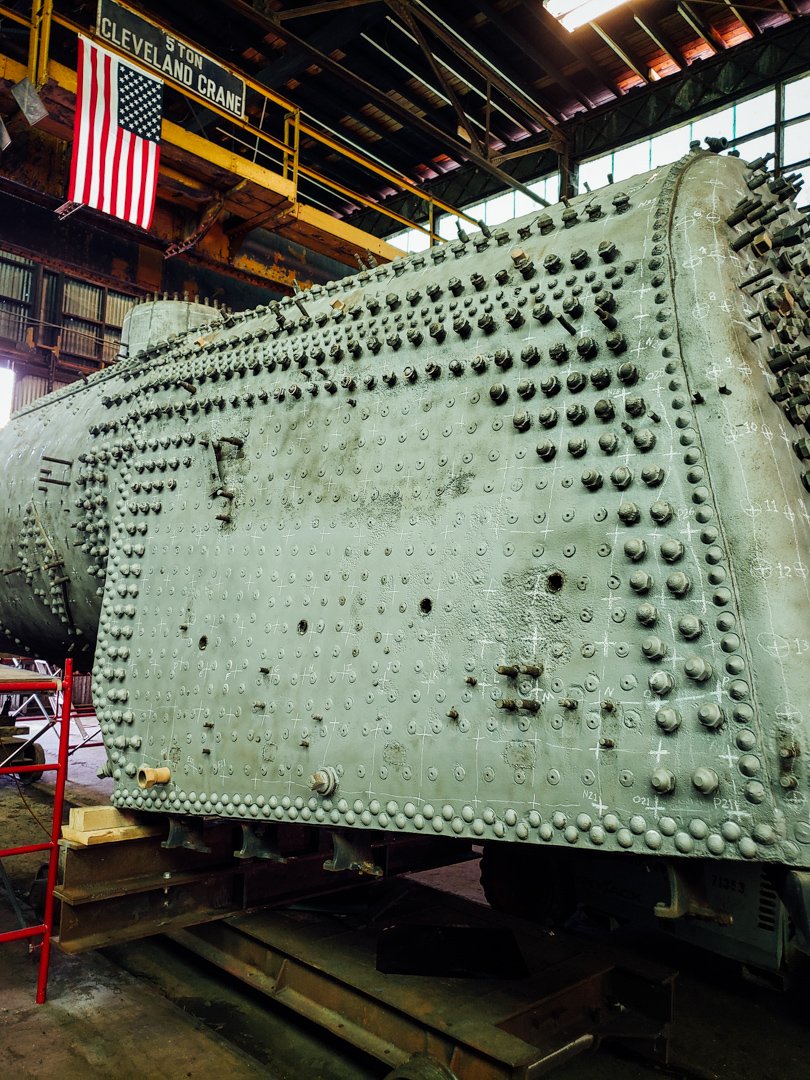

150-TON PRESERVATION PUZZLE

Since late 2021, the former Lucey Boiler shop in Chattanooga, Tennessee, has been host to a puzzle weighing 150-tons.

Throughout the shop’s 52,000 square feet, hundreds of components that together form Atlantic Coast Line steam locomotive No. 1504 have been carefully disassembled, inventoried, inspected, cleaned, and laid out like a 1:1-sized model kit. The project is equal parts historic preservation as it is an investigative riddle.

Built in 1919, No. 1504 spent decades hustling across the southeastern United States in passenger and freight service – one of the thousands of light Pacific-type locomotives that operated in the 20th Century. The historic locomotive was selected by the railroad for preservation in 1953 and later it was placed on public display in downtown Jacksonville, Florida in 1960 at the new headquarters of the Atlantic Coast Line. Nearly 70 years later, No. 1504 was selected for a new era of service as part of the Sugar Express, a new regional tourist railroad attraction in South Central Florida.

A MODERN RAIL TOURISM ATTRACTION EMERGES IN FLORIDA

U.S. Sugar, and its subsidiary Sugar Express, is a recent addition to rail preservation and tourism in Florida. Committed to celebrating its corporate heritage, U.S. Sugar commissioned FMW Solutions to complete the restoration of its very own steam locomotive no. 148 in 2019. Built for the Florida East Coast Railway and later owned by U.S. Sugar, No. 148 came back to life in 2020 after an extensive overhaul, and it has been operating in seasonal tourist rail service since that time. In the interim, FMW’s restoration team has been focused on steadily rebuilding the railroad’s growing fleet of vintage passenger cars, and diligently inspecting a missing link in the railroad lineage of Sugar Express – the Atlantic Coast Line.

U.S. Sugar’s freight railroad, the South Central Florida Express, operates over nearly 200 miles of track that was originally built by the Florida East Coast Railway (between Fort Pierce and Lake Harbor) and the Atlantic Coast Line Railroad (between Sebring and Lake Harbor, via Clewiston). With No. 148’s heritage as both a U.S. Sugar locomotive and one that was originally owned by the FEC, U.S. Sugar leadership sought to acquire a locomotive from its other predecessor railroad - the ACL. Thus enter No. 1504.

THE RESTORATION BEGINS

Knowing that No. 1504 had languished in salt-laden air for decades, FMW was prepared to battle the effects of this corrosive fog as the engine was first disassembled in Jacksonville for temporary relocation to Tennessee. Entire sections of the locomotive weren’t just rusted together, but fused together by the brine. In just one example of its condition, when No. 1504 was initially moved from its original display site at CSX headquarters to the former Jacksonville Terminal in 1986, its mammoth driving wheels refused to move even then.

While preliminary inspections had been performed at the locomotive’s former display site in Jacksonville, Florida, the true nature of a locomotive’s condition could only be observed through disassembly. The painstaking process has recently ended, and No. 1504 is now entering a new phase – and it will soon be on the move again. For a while, 1504’s components will be circulated even further, as if returning to the various shops at the American Locomotive Works in 1919.

“The locomotive has been stripped down to its most fundamental components, but the salt air corrosion was most notable when we were removing the wheels from the frame,” explained FMW VP-Mechanical Shane Meador. “The shoes and wedges had rusted to such a point that our team had to use hydraulic jacks to remove the diving boxes from the frame. Each item is currently being media blasted for inspection, repair, or replacement.”

A detailed boiler survey has been completed and boiler engineering is underway to determine the minimum thickness permissible for each part of the boiler. Once that has been completed, repairs will be made to the boiler and firebox, preparing it to re-enter service.

Due to corrosion, 1504’s tender tank will be replaced entirely, just as was required for the tender of USSC No. 148. The brand-new tender will be built to original specifications with one exception: it will be converted to burn sustainable, used cooking oil just, as No. 148 does.

Everything else – including rods, bearing boxes, and various appliances – will be dispatched to the machine shop of FMW Solutions in Soddy-Daisy, Tennessee where they will undergo the same specialized surgery that’s helped furnish completed steam and diesel locomotive parts for dozens of other restoration efforts.

The driving wheels have already been shipped to the Tennessee Valley Railroad Museum’s Soule Shops, where FMW crews will use their specialized machine tools to overhaul the 73-inch diameter wheelsets. Regardless of whether the work takes place at FMW’s Soddy-Daisy facility or TVRM, the restoration will honor No. 1504’s status as a National Historic Mechanical Engineering Landmark.

THE NEXT STEPS

While a completion date has not yet been determined, the pace of the restoration will be measured gradually as No. 1504’s various components settle into new temporary homes and facilities. As No. 148 enjoys her busiest steam excursion season yet, the first phase of No. 1504’s rebirth is concluding. Excursions and events behind No. 148 have been warmly received in South Central Florida and a list of 2023 events can be found at sugarexpress.com.